IPC/WHMA Quality and Testing

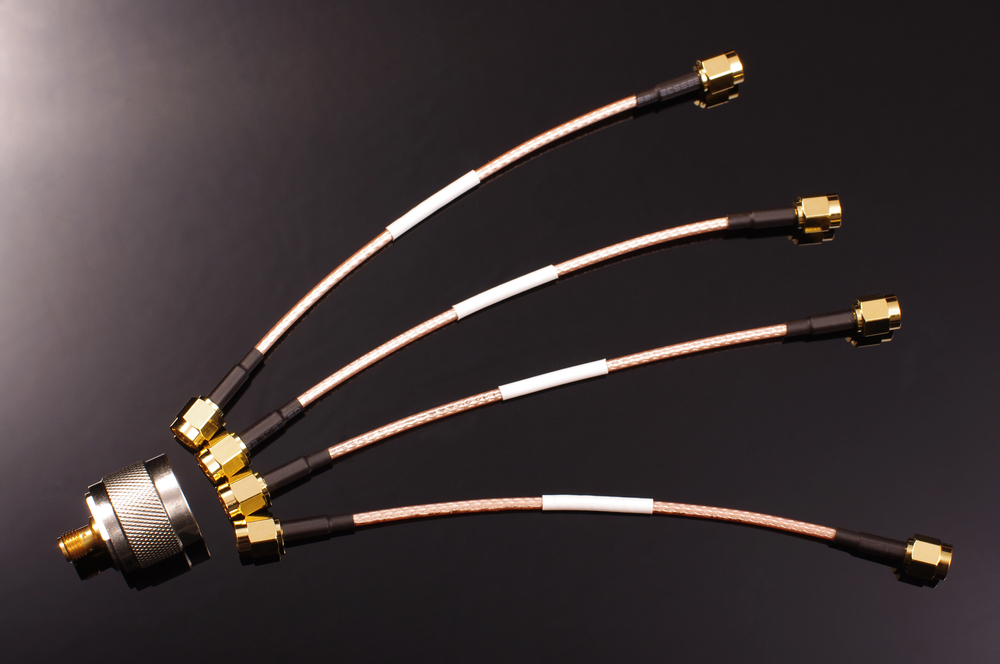

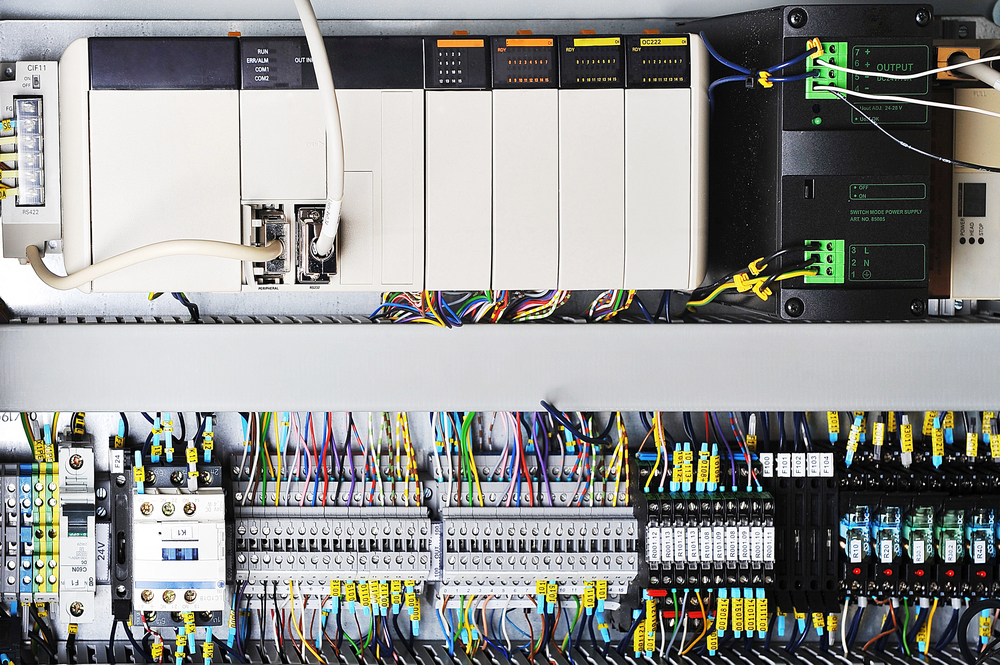

We build to IPC/WHMA-A-620 workmanship with trained operators and documented processes. Every assembly can be 100% inspected and tested to your specification.

- Electrical tests: continuity/open/short, hipot/insulation resistance, and functional tests as required.

- Mechanical assurance: crimp height and pull-force verification, strain relief checks, and overmold integrity.

- Traceability: lot/batch tracking and traveler documentation.

- Documentation: PPAP/FAI support where needed and complete build records.

Engineering Support

Our engineers collaborate early to reduce risk, cost, and lead time.

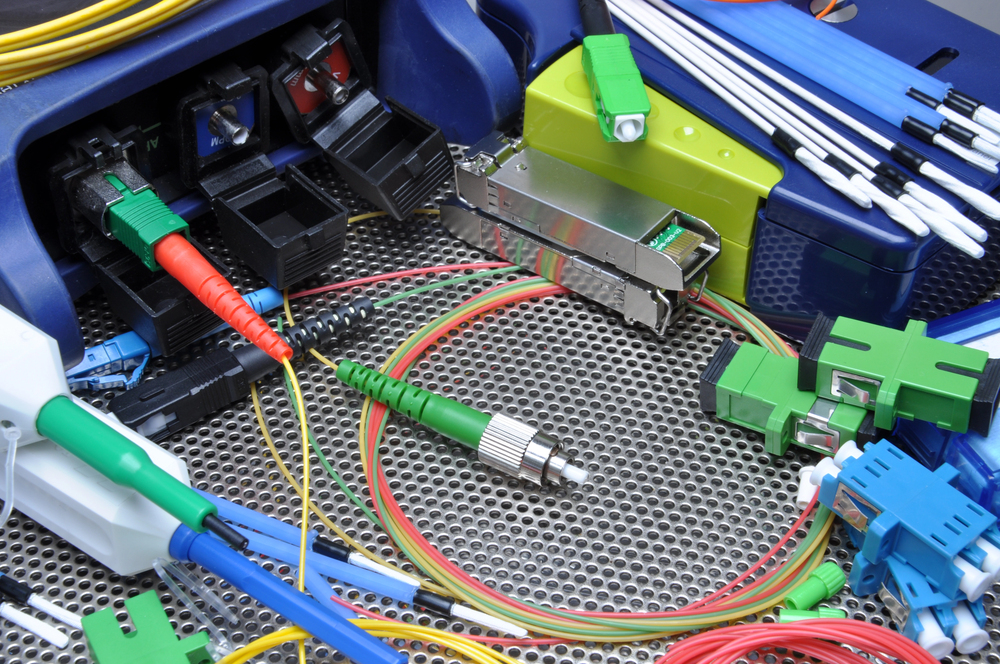

- DFM/DFx reviews: connector selection, crimp specs, bend radius, strain relief, and overmold design.

- Drawings & documentation: we help create or refine drawings, callouts, and test plans.

- Samples & prototypes: quick-turn builds for fit, form, and function.

- Design transfer: seamless handoff from prototype to production with controlled revisions.

- Alternatives: vetted substitutes for EOL or constrained components.

Reliable delivery and professional presentation for every build.

- Lead times: forecast-driven planning with expediting options.

- Kanban/VMI: inventory programs to support stable supply.

- Labeling & barcodes: customer-specific labels, lot codes, and serialization.

- Packaging: ESD-safe, moisture barrier, clean packaging, and protective reels/spools.

- Documentation: C of C, test reports, and packing lists included as specified.

Send your drawings, BOM, and specifications along with target quantities, required tests, and delivery expectations. We respond quickly with clarifying questions (if any) and a firm quotation.

- Accepted files: PDF, STEP, DXF, XLSX/CSV for BOMs.

- Please include connector part numbers and test requirements.

- Prototype and production quantities welcome.

Response time: typically within 1–2 business days.